The Device Story

Owner Ken Anthony has been a craft beer lover since the mid-1980's. Every Friday his dad would buy a pizza from the neighborhood pizzeria and a six pack of Anchor Steam. At the end of the meal, Ken's dad would give him the last sip or two of his beer. Ken had stolen a few sips of beer from kegs at picnic events, so he knew the difference between craft beer and the domestic beer that had dominated the market for decades. This discretion and preference for craft beer followed him into his adulthood.

Ken attended the University of California San Diego's Jacobs School of Engineering, earning his BS and MS in Structural Engineering. By this time, the craft brew revolution was well underway and San Diego was leading the charge in California. He frequented local breweries such as Alpine, AleSmith, Pizza Port, and Stone Brewing. One day, he was returning a keg to Alesmith after a birthday party at his home. A friendly man greeted him at the door to the brewery to accept the keg return and refund the deposit. The man fumbled around a bit to find the paperwork and remarked, "I own the place but I can't find anything in the office." He introduced himself as Pete, and invited Ken and his wife Melissa back to the makeshift tasting area to sample some fresh brews. The tasting room was not yet open for the day, so it was just the three of them sampling beers and talking about his brewery. When asked how he got into the brewing business, Pete said that he had attended USD for law school and later decided that he preferred brewing beer to practicing law. Ken thought that if a successful lawyer would leave a career he'd worked so hard to obtain, there must be something very special and rewarding about running a brewery. He also thought, "maybe I can do this too someday...".

Ken's friend Justin introduced him to the world of homebrewing when Ken was in college. In the beginning, they were brewing extract batches on the stove top, using a funnel filled with ice as a wort chiller, and fermenting in the closet. The beer was lackluster at best, but was the start of something so much bigger. Before long they were all-grain brewing, temperature controlling fermentation, kegging the beer and hosting tasting parties. The guys talked about opening a small brewery in San Diego but were routinely deterred by the overwhelming cost and difficulty associated with such a start up.

In September of 2011, Ken and Melissa welcomed their first child into the world. Being Northern California natives and wanting to be close to family, Ken transferred to his company's Sacramento office and relocated his family back to Northern California. Now, completely on his own, Ken started to secretly make plans to open his brewery. He continued to brew batches as fast as he could empty his fermenter. He would often brew the same beer three or four times in a row, making subtle recipe changes, until it was just right.

One Saturday afternoon in 2012 while they were at Pangaea Bier Cafe, Melissa was enjoying an AleSmith Speedway Stout. She said, “If you can brew an imperial stout even close to as good as this one, I’ll agree to us opening a brewery.” Challenge accepted.

By late 2012 they were on the hunt for a space to rent. They looked at space after space, but nothing seemed to be the right fit for their vision. Finally, their agent, who was running out of options, decided to show them a space that had once been a bustling cafe that catered to the people who worked in the Power Inn industrial area. After two decades of success, it closed down and the space became a revolving door for failed delis, cafes, and caterers. It was small, about 1,600 sf, had a kitchen grease hood, walk-in cooler, bathrooms, HVAC, floor sinks, and natural gas. This was exactly what Ken was looking for. All this infrastructure represented hundreds of thousands of dollars that they wouldn’t have to spend. More importantly, dollars they didn’t have to begin with. Part of their vision was to open this brewery completely on their own, with no partners, no investors, and no bank loans.

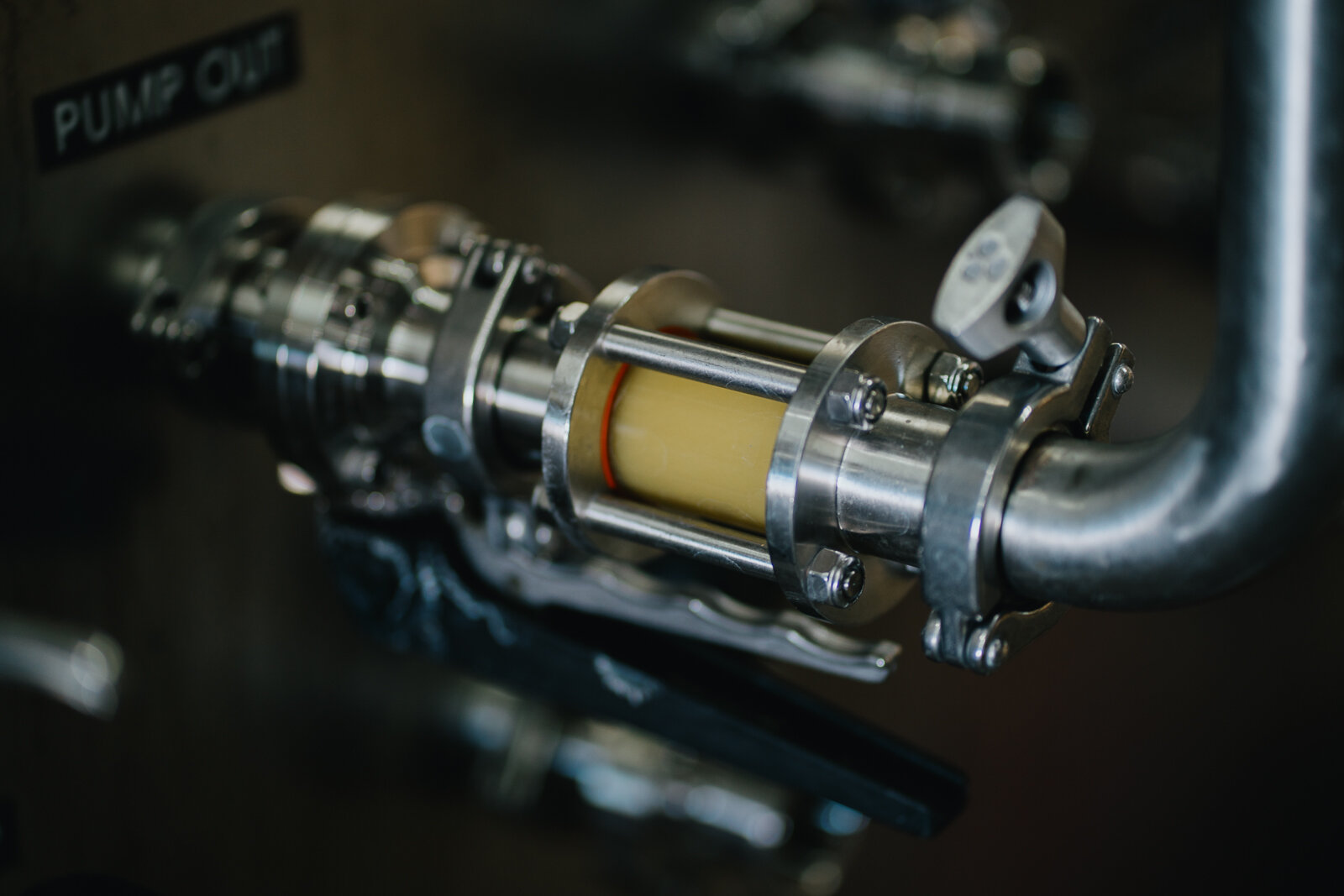

In April of 2013, they were handed the keys to the space and away they went! Ken assembled his then “nano brewery” with a one-barrel brewhouse and four 3-barrel plastic fermenters that were temperature controlled using window AC units inside boxes that his friend Jack helped him build. He converted a stainless steel sink into a keg washer and washed them one-by-one with three separate passes: caustic soda, acid, and sanitizer. Washing just a few pallets of kegs took about twelve hours. In contrast, the keg washer at Device now washes three pallets an hour.

Ken’s next door neighbors in Suite B were Rocky and Derek. They ran a small wood and metal fabrication shop. They were instrumental in getting the brewery taproom built. The entire bar was fabricated in their shop, among many other things. Countless odd tasks were completed with the help of Rocky and Derek. Their talent, expertise and unbelievable generosity was ultimately what made it possible to open the taproom by the end of 2013.

Device beers are now distributed throughout Northern California from San Francisco to Lake Tahoe, and Bakersfield to the Oregon border in more than 2,500 retail accounts. Ken and Melissa opened the ICE Blocks Midtown Taproom in June 2018 and opened the 7,000 sq ft Pocket/Greenhaven Kitchen and Taproom in February of 2020.

THE BREWERY

THE DEVICE BREWING Custom TWIN 20 BARREL BREWHOUSE

Brewhouse:

Custom-Made Twin 20 BBL 3-Vessel System Supplied by a Premier Stainless 30 BBL Hot Liquor Tank, 1600 lb Grist Case with 4" Grist Hydrator, V-Wire False Bottom, and 15 gallon Grant.

Fermenters:

Eleven 30 BBL, Two 40 BBL, and One 15 BBL Cylindro-conical Unitanks. Our beers are fermented, dry-hopped, fined, and carbonated in a single tank.

CANNING LINE:

CODI 6-Head Counter-pressure filler made in Golden, Colorado. Depalitizer, ionized air blower, date-coder, seamer, washer/dryer, label applicator, and PakTech applicator.

Process:

Our typical brew day starts very early in the morning. We circulate 165F water through a spray ball in the mash tun to preheat. Our milled grain is loaded from one of our silos into the grist case where a computer monitors the total weight. The hot liquor tank delivers hot water into the grist hydrator as the malt falls into the mash tun. This process takes about 40 minutes depending on the size of the grain bill. After a single mash rest, the vorlauf begins and continues until the wort has clarified. After that, the runoff starts along with sparging until the boil kettle is full and desired pre-boil gravity is achieved. The wort is boiled with hops, a whirlpool is performed, and the knockout is commenced through a stainless steel heat exchanger. The chilled wort is moved into a clean, sanitary fermenter and the line is chased with 185F water. A yeast sample is then taken from the brink and placed under a microscope. A cell count and viability test is performed to determine the density and health of the yeast slurry. The required number of healthy yeast cells required is calculated (for Basilica, roughly 12 trillion cells!) and the appropriate poundage of yeast slurry is determined and injected into the fresh, oxygenated brewers wort in-line. The temperature is set on our cellar computer and the fermentation begins.